|

◎ 新设备 ◎ 三臂设备 ◎ 梭式设备 ◎ 摇摆设备

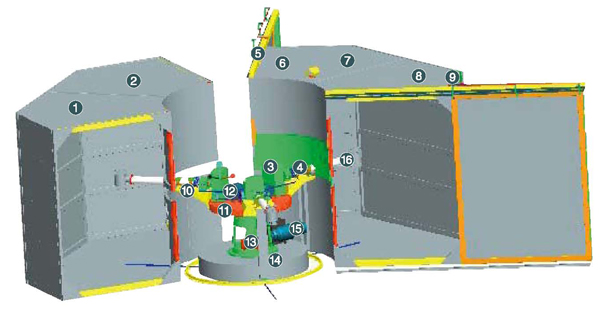

《TG3SS-150A》是塔式双室3臂自控滚塑机,三条独立运动的工作臂互成120°夹角,分别置于三

个工位,进行不同要求的工作。当一个工位完成后,由计算机系统自动转入下一程序。也就是说当一个工位加热结束后,自动转入冷却室,冷却室工位转入装卸工位,装卸工位转入加热室,连续循环,生产效率较高,热能利用充分。中心控制室由工控机可编程序控制器(PLC)、显示器、温控器等组成。自动控制各工作轴的转速转向,升温速度、升温时间、自动开门、关门、冷却状态等程序动作。各工位程序互锁,并不会互相干涉,所有动态,均在显示器中显示。

The brief analysis of

bi-capacity tri-arm tower rotational molding

machine

The bi-capacity tri-arm tower

rotational molding machine is automatic.The three

working arms are at an included angle of 120 degree

between each other , they can work under different

requirements in three carts respectively. When one cart

is finished, the computer system will turn to next

program.,i.e,when one cart completes heating, it goes

into the cooling room automaticlly. The cart in the

cooling room then transfers to the loading/unloading

station, then to the heating room, unceasingly cycling

in this way, the production efficiency is higher and

energy also can be made full use. The central control

room is made up of PLC,screen, temperature controller

and so forth. It can control the turning speed and

direction ,temperature rising speed and time, door

opened and closed automaticlly, cooling condition of

each axle. All the carts will not be intervened by each

other, and the whole process movements will be shown on

the screen.

三臂设备

Bi-capacity Tri-arm Tower

Rotational Molding Machine

| 说明Instruction |

|

|

|

| ①冷却室 cooling room |

②冷却风机 Fan-cooled machine |

③减速机 Reducing machine |

④主轴 Main axle |

| ⑤热室移门 Moving door |

⑥燃烧室 Combustion space |

⑦热风道 Hot air duct |

⑧燃烧机 |

| ⑨移门电机 |

⑩拖架 Bracket |

⑾工作转台 Waking turntable |

⑿主轴电机 |

| ⒀塔台支架 |

⒁基础 Base |

⒂塔台动力 Control tower motor |

⒃模架连接头 |

设备优点:

精加工浇铸机架、坚固耐用、不易变形。

一出二传动输出,节约能源,减少机械故障。

整体设计思路清晰,机械、电路布置创新、实用。 |