|

◎ 新设备 ◎ 三臂设备 ◎ 梭式设备 ◎ 摇摆设备

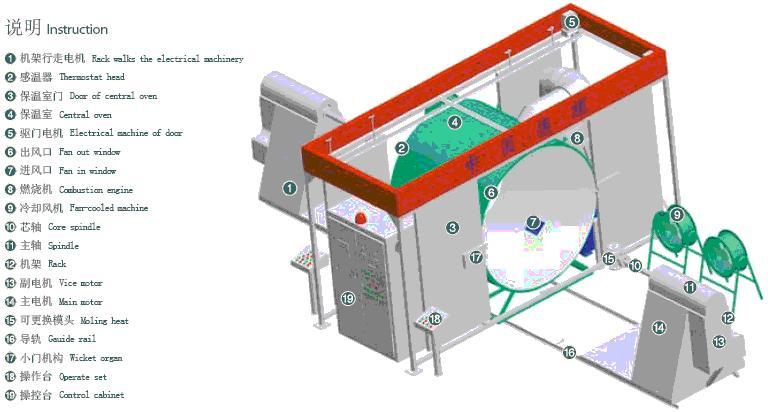

《SGZ-350A》主要是由一个固定加热室、二个移动工位组成的。当一个工位进行加热滚制时,另一个可以冷却卸模。所有参数包括:主机转速、副机转速、升温时间、升温速度、滚制时间、温度上限、自动行走、热风循环、自动开关门等,都由计算机自动控制,并以实时计点的方式在显示屏上形成一条实时加工的工艺曲线图。两个工位独立工作,互不干涉,程序互锁。

Shuttle Rotational Equipment Brief Introduction of shuttle rotational equipment The shuttle rotational equipment is mainly made up of one central oven and two movable carts. When a cart is being heated and rotating, the other can be cooled and unloaded. All parameters which include the main machine turning speed, the vice motor turning speed, time and speed of temperature rising, rotational time, the maximum temperature,automatic movement, hot air circulation, automatically opening and closing of door and so forth, are controlled automatically by computers and will be shown as a curve chart on the screen in the way of synchronous computation. The two carts work separately and do not intervene each other.

三臂设备

Bi-capacity Tri-arm Tower

Rotational Molding Machine

| 滚塑机技术参数表 Technical Parameters of Rotational Moulding Equipment |

| |

|

《SGZ-250A》 |

《SGZ-350A》 |

《SGZ-350B》 |

《SGZ-400A》 |

《TGSS-165A》 |

| |

主轴中心高 |

1400 |

2150 |

2150 |

2400 |

1650 |

| |

传动方式 |

齿链组合 |

齿链组合 |

齿链组合 |

齿链组合 |

齿链组合 |

| |

控制执行 |

工控机+PLC |

工控机+PLC |

工控机+PLC |

工控机+PLC |

工控机+PLC |

| |

热室容量 |

Φ2500×2000 |

Φ3500×2400 |

Φ3500×3000 |

Φ4000×3000 |

3000×2600×3500 |

| |

控温范围 |

0~499℃ |

0~499℃ |

0~499℃ |

0~499℃ |

0~499℃ |

| |

调速范围主 |

0~28r/min |

0~25r/min |

0~25r/min |

0~25r/min |

0~25r/min |

| |

调速范围副 |

0~22r/min |

0~20r/min |

0~20r/min |

0~20r/min |

0~20r/min |

| |

速差 |

≤8% |

≤8% |

≤8% |

≤8% |

≤8% |

| |

门移速度 |

0.2m/s |

0.2m/s |

0.2m/s |

0.2m/s |

0.2m/s |

| |

主机移动 |

0.2m/s |

0.2m/s |

0.2m/s |

0.2m/s |

12m/s |

| |

加热型式 |

热风循环 |

热风循环 |

热风循环 |

热风循环 |

热风循环 |

| |

升温速度一级空载 |

38~42/min |

10~30/min |

10~28/min |

10~30/min |

10~32/min |

| |

升温速度二级空载 |

40~45/min |

10~40/min |

10~38/min |

0~34/min |

10~42/min |

| |

装机容量 |

16kw |

20kw |

24kw |

34kw |

26kw |

以上是目前本公司已经制造过的梭式设备和三臂设备

Our company has already made the above equipments(shuttle and tri-arm rotational) |